|

| |

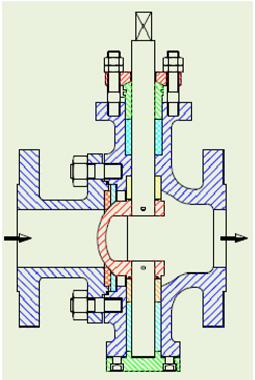

V- NOTCH BALL VALVE SERIES MIC -421 |

Manufacturer, Exporter, Wholesaler and Supplier of Automation and Instrumentation Products such as V-NOTCH BALL VALVE SERIES and our setup is situated in Pune, Maharashtra, India.

|

INTRODUCTION

The V–Notch Ball Valve gives non-clogging, high capacity,

straight through flow control of fluids containing pulp and

paper stock or slurries and fluids containing suspended

solids or fibrous materials. V-Notch Ball Valve is quarter

turn valve with a segment Ball. The V-Ball create a wedging

and shearing effect prevent the dragging of stock or slurry

between the ball and its seal the

V- Notch Ball Valves are offered squared and clamped

driven shaft plus ball shaft with splined connection

designed for zero lost motion for highly accurate

positioning and precise control.

|

|

| |

| |

| |

| SPECIFICATION : |

DESIGN |

BS. 5351 |

| SIZE |

25 to 200 mm (1" to 8") |

| RATING |

ANSI 150 |

| END CONNECTION |

Flanged End |

| F/F DIMENSIONS |

ANSI B-16.10 |

| FLOW CHARACTERISTICS |

Modified Equal Percentage,

Linear, On-Off. |

| FLOW DIRECTION |

Forward (into convex face of V-ball) |

| MAX. BALL ROTATION |

90˚ |

| BODY MATERIAL |

Carbon Steel, Stainless Steel, and Alloy

Steel etc. |

| BALL MATERIAL |

CF8M Chrome plated/Alloy steels. |

| SEAT RING |

PTFE, Carbon Filled Teflon. |

| BALL RING |

CF8M, Alloy steels |

| GASKET |

PTFE, Graphite Laminate. |

| GLAND PACKING |

PTFE V Rings, Grafoil. |

| ACTUATOR FORM |

Diaphragm, Rotary, Electric |

| ACTUATOR TYPE |

Scotch |

| DIAPHRAGM |

Nitrile / Neoprene |

| SPRING RANGE |

3 – 15 Psig (0.2 – 1.0 Kg/cm²) |

| 6 – 30 Psig (0.4 – 2.0 Kg/cm²) |

| AIR SUPPLY |

20 – 35 Psig (1.4 – 2.5 Kg/cm²) |

| AIR CONNECTION |

1/ 4" or 1/ 2" NPT |

| ACCESSORIES OPTIONAL |

Valve Positioner – Pneumatic,

Electro Pneumatic, Smart, Airset,

Solenoid Valve, Air Lock,

Volume Booste, Position Transmitter,

Limit Switches etc.

Top or Side Mounted Handwheel |

|

| |

|

| |

V-NOTCH BALL VALVE

|

DESIGN FEATURES :

- A Shearing effect between the ball and seal ensures tight shut-off, even on fibrous slurries.

- The unrestricted, straight – through flow design provides high capacity and wide

rangeability.

- Precise contouring of the V-notch balls provides a nearly equal percentage characteristic.

- Replaceable ball seal and back up ring for added rigidity.

- Ball machined to a super smooth finish, hard – chrome plated and polished to increase Ball

seal life.

- High Cv to body size ratio.

|

QUALITY AND PERFORMANCE GUARANTEE :

- Produced with Quality Systems accredited to ISO 9001: 2008 by Bureau Veritas.

- Full material certification available for all major component Parts.

- Full guarantee on design and Performance.

- All testing are performed to the requirements of ANSI B16.34.

|

|

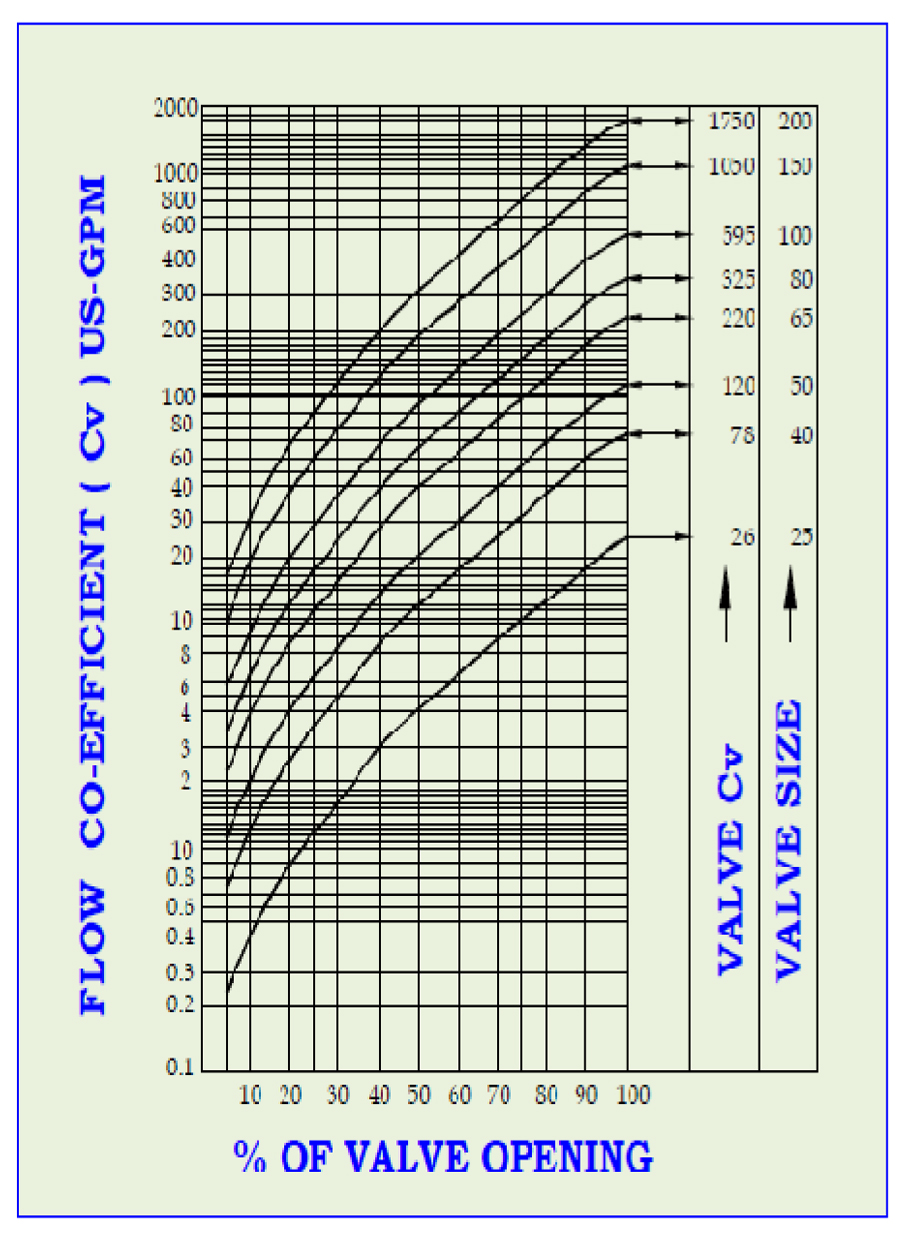

VALVE SIZING CO-EFFICIENT Cv RATING

|

| VALVE SIZE |

Inches |

1 |

11/2 |

2 |

21/2 |

3 |

4 |

6 |

8 |

| mm |

| |

|

25 |

40 |

50 |

65 |

80 |

100 |

150 |

200 |

| Cv (MAX.) AT 90º OPENING |

26 |

78 |

120 |

220 |

325 |

595 |

1050 |

1750 |

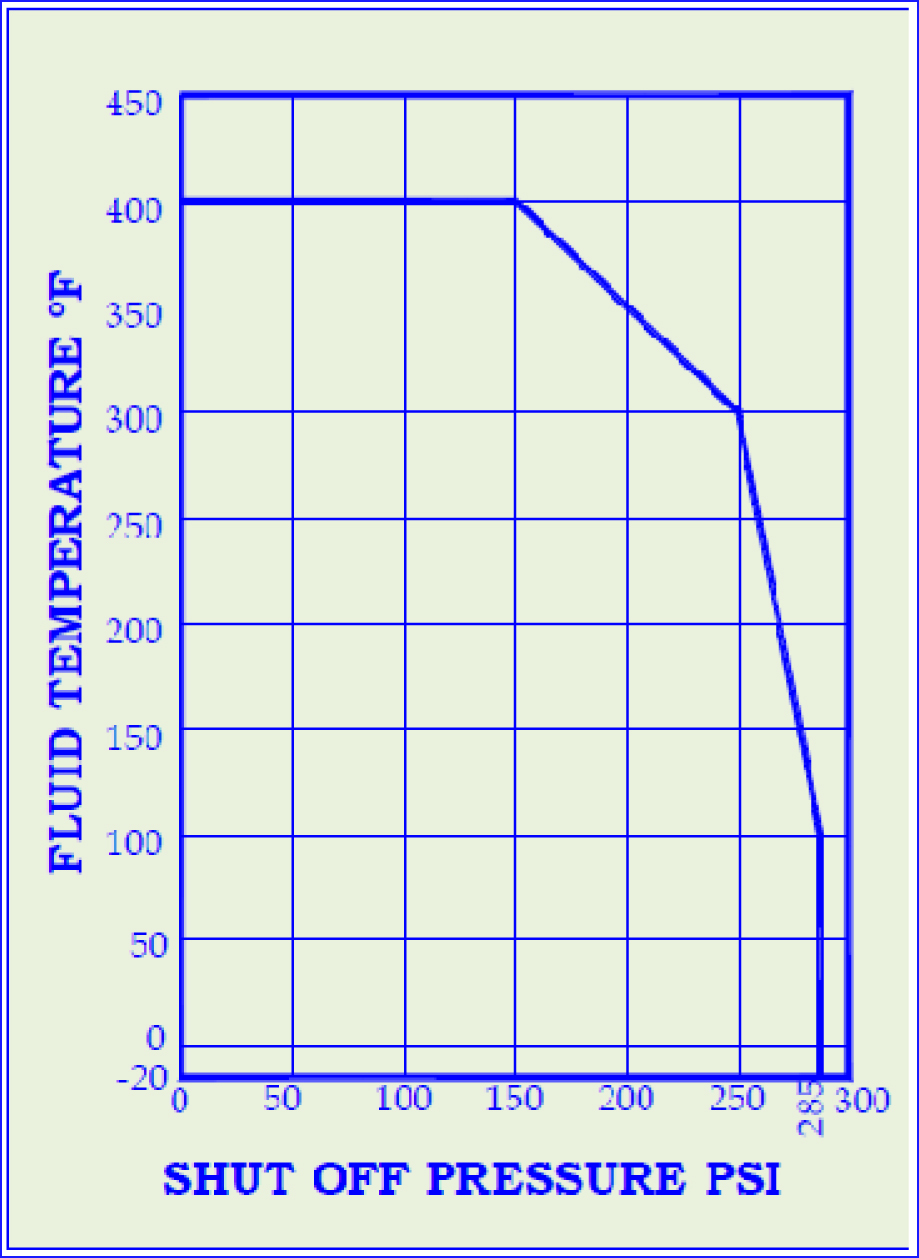

PRESSURE / TEMPERATURE

FOR PTFE BALL SEALS |

FLOW CHARACTERISTIC

CURVES 90º OPENING |

|

|

|

|

|

|

| |

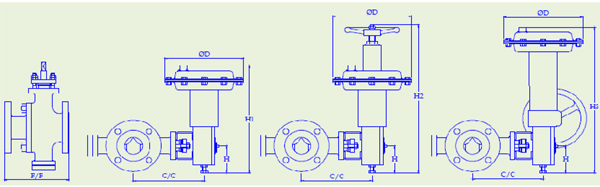

MOUNTING DIMENSIONS FOR V-NOTCH BALL VALVE

VALVE

SIZE |

ACTUATOR

MODEL |

FACE TO FACE |

C / C |

Ǿ D |

H |

STD |

TMH |

SMH |

| ANSI 150 |

H1 |

H2 |

H3 |

15 |

MIC-141-90º |

108 |

188 |

218 |

85 |

328 |

488 |

-- |

25 |

MIC-166-90º |

127 |

248 |

286 |

100 |

432 |

639 |

635 |

40 |

MIC-166-90º |

165 |

280 |

286 |

100 |

432 |

639 |

635 |

50 |

MIC-166-90º |

176 |

273 |

286 |

100 |

432 |

639 |

635 |

65 |

MIC-106-90º |

190 |

301 |

371 |

100 |

466 |

673 |

670 |

80 |

MIC-106-90º |

203 |

301 |

371 |

100 |

466 |

673 |

670 |

80 |

MIC-251-90º |

203 |

306 |

443 |

160 |

657 |

944 |

907 |

100 |

MIC-251-90º |

229 |

368 |

443 |

160 |

657 |

944 |

907 |

150 |

MIC-251-90º |

267 |

396 |

443 |

170 |

667 |

954 |

917 |

150 |

MIC-411-90º |

267 |

430 |

616 |

190 |

768 |

N/A |

1073 |

200 |

MIC-411-90º |

292 |

502 |

616 |

190 |

768 |

N/A |

1073 |

|