GLOBE 2 WAY CONTROL VALVE SERIES MIC -221

Manufacturer, Exporter, Wholesaler and Supplier of Automation and Instrumentation Products such as GLOBE 2 WAY CONTROL VALVE SERIES MIC and our setup is situated in Pune, Maharashtra, India.

INTRODUCTION

This type of Valve with its classic globe body shape, which reflects its name, uses the variable area generated between the plug and seat to control fluid flow. It is very versatile offering reduced trim options as well as a variety of special trims for severe high pressure drop applications.

This style of valve is easily adapted for use on cryogenic temperatures and for high temperature duties. This valve is preferred for tight shut–off, positioning accuracy,high range ability and simplified maintenance, satisfy the majority of control valve applications throughout the process and power industries in control of Air, Steam,

Water, Gas, Chemicals etc.

|

|

| |

| SPECIFICATION : |

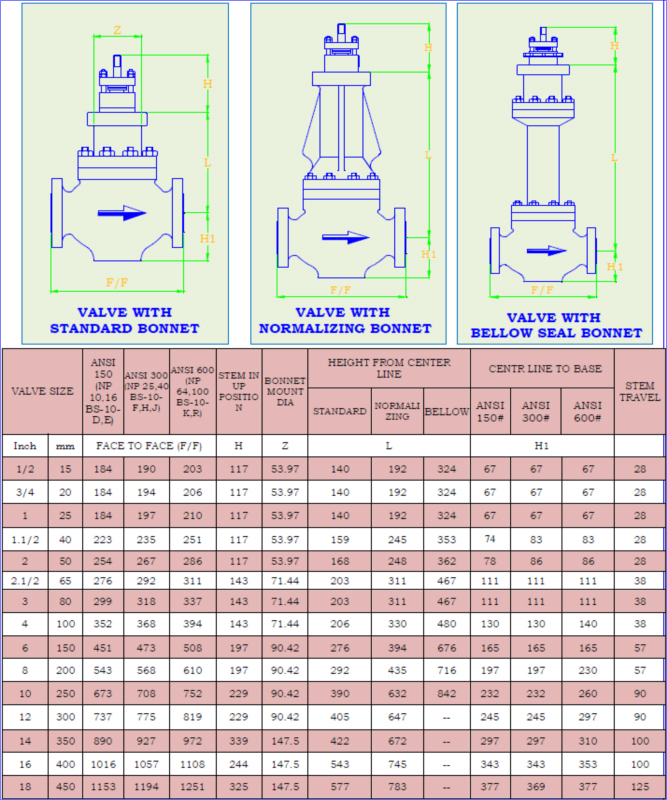

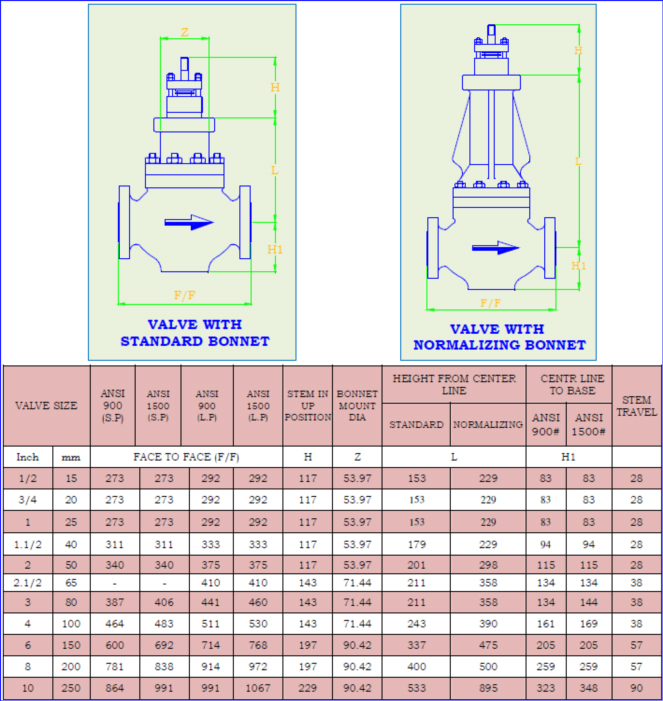

DESIGN |

ASME B16-34 |

| VALVE SIZE |

15 to 450 mm (1/2" to 18") |

| RATING |

ANSI 150 to 2500 or Equivalents to BS, DIN, etc. |

| FACE TO FACE |

ISA S.75.03 up to 600# ISA S.75.16 900# and above. |

| END CONNECTION |

Flanged, Screwed, Butt Weld, Socket weld. |

| BODY MATERIALS |

Carbon Steel, Chrome-moly Steel, Stainless Steel, Monel, Alloy20, Hastelloy

B/C, Duplex Stainless Steel, Aluminum Bronze, PP, PTFE etc.

: PTFE Lined / PTFE Metal Housed |

| BONNET |

Standard upto 250°C

: Normalizing (Finned) between 250°C to 500°C

: Extended cold service - 20°C to - 100°C

: Cryogenic - 100°C to - 250°C

: Bellows seals. |

| GLAND PACKING |

Grafoil / PTFE V Rings, Low Emission |

| TRIM DESIGNS |

Top Guided Contoured, Splined MS Flow, V-Ported (Balanced

/ Unbalanced), Low Noise (LN1, LN2, LN3, LN4) |

| TRIM MATERIALS |

Stainless Steel, Alloy20, Monel, Duplex Stainless Steel, 13%

Chrome Steel Hastelloy B/C, Stellite (Alloy 6) |

| CHARACTERISTICS |

Equal Percentage, Linear and Quick Opening. |

| SEAT LEAKAGE |

As per ANSI/FCI-70-2 Class III. IV, V and VI (STANDARD

LEAKAGE RATES) Metal to Metal Seating Class IV, Less than

0.01% of rated Cv. Metal to Soft Seating

–

Bubble tight (Zero

Leakage) |

| ACTUATOR TYPE |

Diaphragm, Piston or Electric. |

| ACTUATOR ACTION |

Direct / Reverse Acting. |

| DIAPHRAGM |

Nitrile / Neoprene |

| SPRING RANGES |

3–15 PSIG (0.2–1.0 Kg/cm2)

: 6 -30 PSIG (0.4-2.0 Kg/cm2) |

| AIR SUPPLY |

20–35 PSIG (1.4–2.5 Kg/cm2) |

| AIR CONNECTION |

1/ 4”or 1/ 2” NPT |

| ACCESSORIES |

Valve Positioner - Pneumatic, Electro Pneumatic, Smart Positioner.

Instruments-

Airset, Solenoid Valve, Air Lock, Volume Booster, Position Transmitter, Limit

–

Proximity Switches etc. |

|

|

|

| |

|

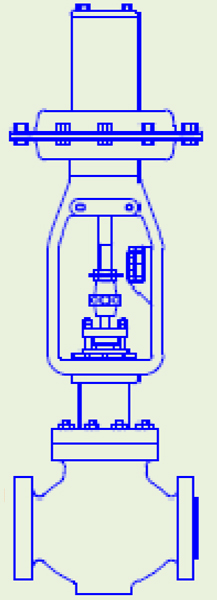

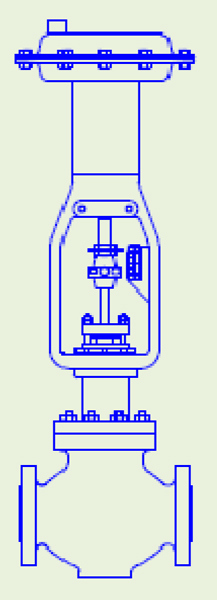

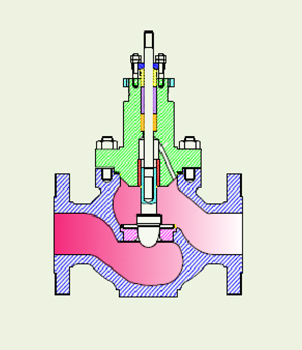

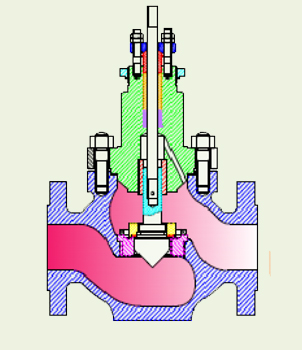

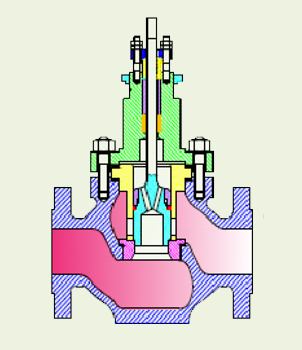

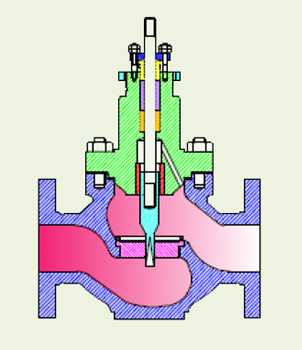

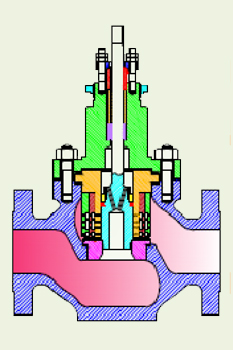

CONTROL VALVE WITH REVERSE ACTUATOR

|

CONTROL VALVE WITH DIRECT ACTUATOR |

|

|

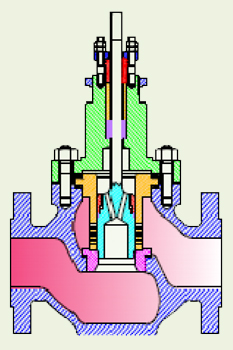

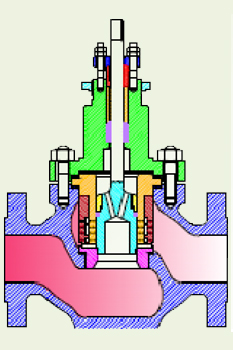

FEATURES :

- Top or Side Mounted hand wheel, Limit Stops

- Removable Blind Head, Steam Jacketing, etc.

|

| |

|

DESIGN FEATURES :

- High flow capacity and range ability.

- Large variety of Trim design.

- Top entry for ease of inspection and maintenance.

- Tight closing for reliable control even when changes in pressure / temperature are sudden

and extreme.

- Bolts located outside of the piping stress area to eliminate gasket crush problems,

- Wide selection of actuators to meet most system requirement.

- Rigorously proven on-site performance.

|

|

QUALITY AND PERFORMANCE GUARANTEE :

- Produced with Quality Systems accredited to ISO 9001 : 2008 by Bureau Veritas and "CE" Marked in accordance to Pressure Equipments Directive and Regulations by Lloyd's Register.

- Full material certification available for all major component Parts.

- Full guarantee on design and Performance.

- All testing performed to the requirements of ASME B16.34.

|

RANGE ABILITY

The Inherent range ability of MSSet standard trims is as given under.

TRIM SIZE |

STANDARD RANGEABILITY |

inch |

mm |

Spline micro

trim |

CONTOURED |

LR trim |

Multi Stage

trim |

1/2 and 3/4 |

15 and 20 |

100:1 |

40:1 |

35:1 |

- |

1 to 3 |

25 to 80 |

80:1 |

50:1 |

45:1 |

40:1 |

4 to 12 |

100 to 450 |

- |

60:1 |

55:1 |

50:1 |

14 to 24 |

350 to 600 |

- |

70:1 |

60:1 |

50:1 |

|

|

MAXIMUM RECOMMENDED VALVE BODY VELOCITY FOR LIQUID FLOWS

| Trim style |

VALVE SIZE |

VALVE BODY MATERIAL |

|

|

CARBON STEEL |

ALLOY STEEL |

Aluminium bronze |

|

Inch |

mm |

m/s |

m/s |

m/s |

Contoured |

½ to 2 |

15 to 50 |

12.5 |

14.0 |

8.0 |

|

3 to 8 |

80 to 200 |

10.5 |

11.0 |

6.5 |

Cage Guided |

1 to 12 |

25 to 300 |

13.1 |

15.8 |

8.0 |

|

12 to 24 |

350 to 600 |

10.7 |

13.1 |

6.5 |

|

MAXIMUM RECOMMENDED VALVE BODY VELOCITY FOR GAS/VAPOUR FLOWS

|

Trim style |

Valve Size |

MAXIMUM |

MAXIMUM |

MAXIMUM OUTLET MACH

No. for predicted noise level |

|

|

Inlet velocity |

Out velocity |

|

|

Inch |

Mm |

m/s |

m/s |

>95dba |

<95dba |

<85dba |

|

Contoured |

½ to 2 |

15 to 50 |

105 |

253 |

0.65 |

0.5 |

0.3 |

|

3 to 4 |

80 to 100 |

90 |

253 |

0.65 |

0.5 |

0.3 |

|

6 to 8 |

150 to 200 |

85 |

253 |

0.65 |

0.5 |

0.3 |

Cage Guided |

1 to 24 |

25 to 600 |

68 |

253 |

0.65 |

0.5 |

0.3 |

|

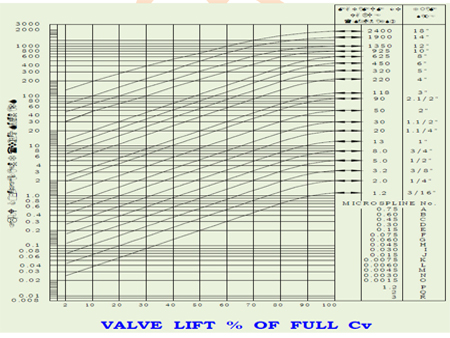

The Inherent flow characteristic of a control valve is the relationship between the flow and the lift of the plug at constant pressure drop.The characteristic normally available are shown

as below.

LINEAR :-Flow is directly proportional to valve lift.

EQUAL%:- Flow change by a constant percentage of its instantaneous value for each unit of valve lift.

QUICK OPENING:- Flow increases rapidly with

initial travel reaching near its maximum at a low lift.

|

VALVE FLOW CO-EFFICIENT / LIFT RELATIONSHIP EQUAL % CONTOURED TRIMS |

|

VALVE SIZING CO-EFFICIENT Cv RATING - 150# TO 2500#

|

VALVE SIZING CO-EFFICIENT Cv RATING - 150# TO 2500#

|

VALVE STRIM: STANDARD RANGE |

| |

CONTOURED TRIM METAL TO METAL

|

CONTOURED TRIM SOFT SEATED

|

|

|

|

|

|

CONTOURED TRIM

(Metal to Metal & Soft Seated)

The Contoured Trim is the standard Top Guided top entry, which provides sure, economical Control for intermediate pressure drop service. A large diameter, precision machined plug and a pressed in, hardened guide bushing constitute the basic elements of a plug guidance system.

Contoured trim available for both modulating duty and on/off duty. The contoured trim configuration available for both metal to metal contact and soft seat to metal contact to give leakage rate in accordance to FCI-70.02 class VI (ANSI B 16.104 class VI.)

|

|

V – PORTED TRIM |

MICRO FLOW SPLINED TRIM |

V – PORTED TRIM

(Metal to Metal or Soft Seated)

• Ported cage trim is a heavy duty cage guided design with the

option of pressure balanced configuration.

• Choice of seal materials provides fluid compatibility.

|

MICRO FLOW SPLINED TRIM

(Metal to Metal or Soft Seated)

• This design of trim is a Seat guided arrangement having a very high

range ability and designed for the accurate control of minute flow rates. |

|

|

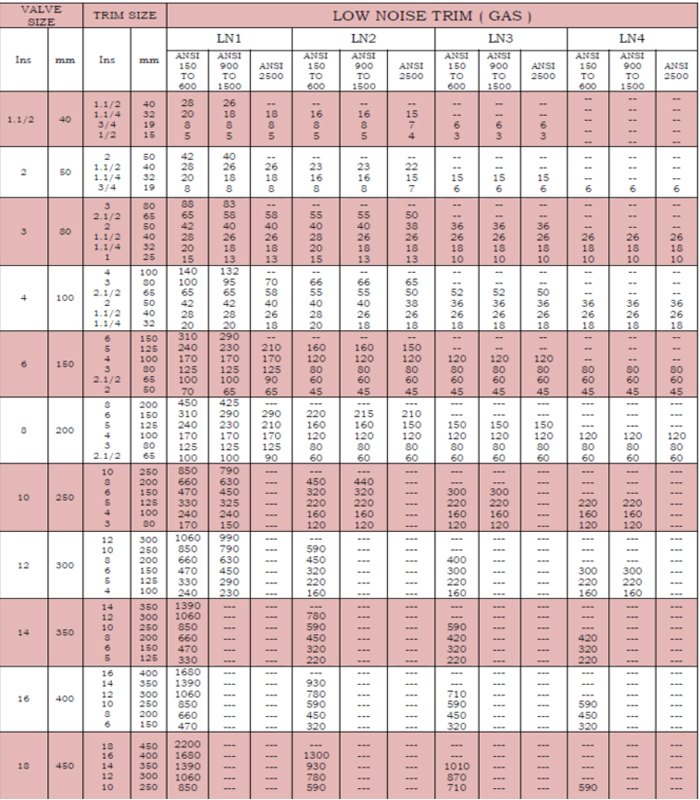

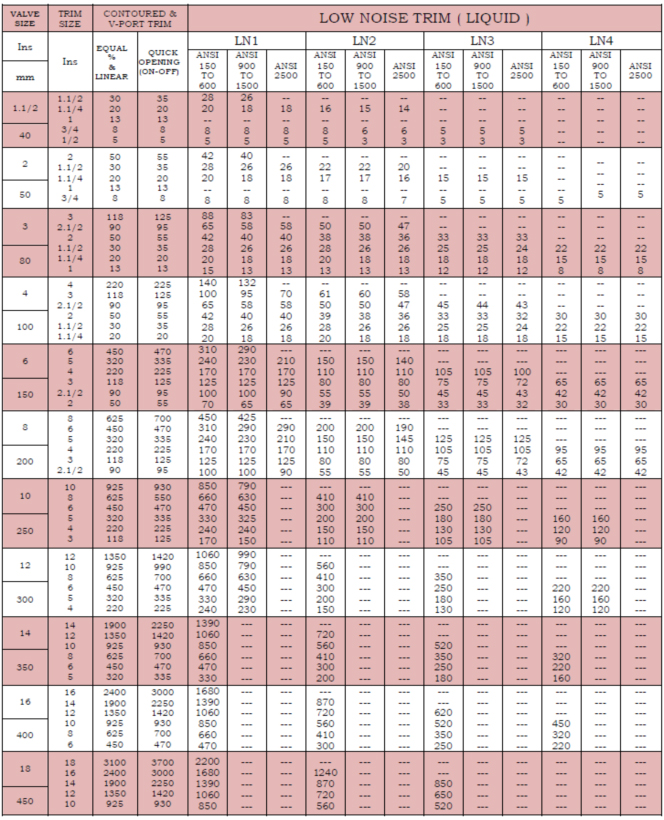

LN1 Single Stage Low Noise

|

LN2 Double Stage Low Noise |

|

|

|

|

|

|

|

|

|

|

|

|

|

LN3 Triple Stage Low Noise

|

LN4 Four Stage Low Noise |

|

|

|

|

LOW NOISE TRIM

(Metal to Metal and Soft Seated)

|

|

• All the advantages of ported cage trims.

• Multiple drilled orifices of a special size and spacing resulting in reduced noise levels compared to

conventional valve trims.

• Added advantage on liquid duty valves by preventing cavitations damage.

• Low pressure recovery characteristic of LN1 suitable for flashing duty.

|

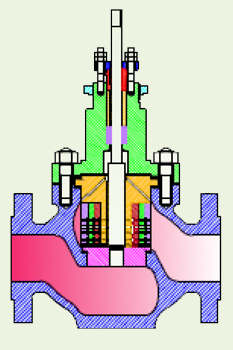

ACTUATOR SELECTION GUIED

|

|

|

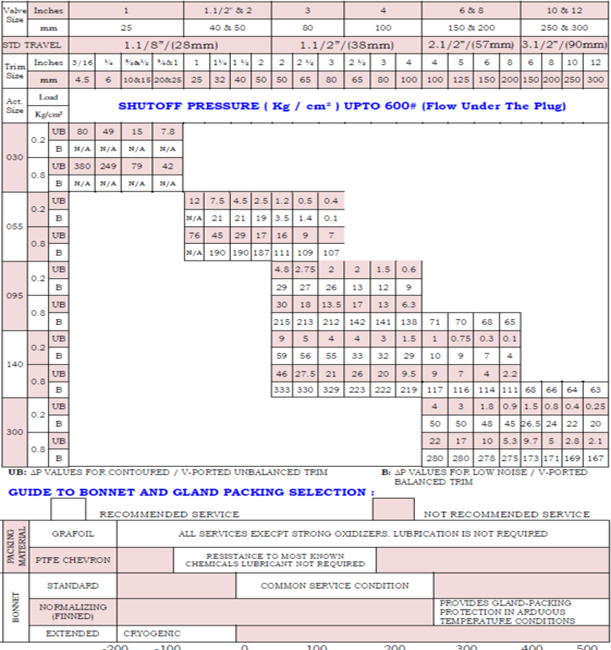

ACTUATOR DIMENSIONS

|

|

| |

|

ACTUATOR

MODEL |

EFFECTIVE

Inch2 |

BONNET

MOUNT

DIA. |

TRAVEL |

ФD |

HA |

HA1 |

HA2 |

HA3 |

HA4 |

HA5 |

MIC-R 141 |

30 |

54 |

28 |

218 |

- |

356 |

- |

494 |

- |

650 |

MIC-D 141 |

30 |

54 |

28 |

218 |

372 |

- |

529 |

- |

650 |

- |

MIC-R 166 |

55 |

54 |

28 |

286 |

- |

494 |

- |

566 |

- |

697 |

MIC-D 166 |

55 |

54 |

28 |

286 |

471 |

- |

678 |

- |

673 |

- |

MIC-R 166 |

55 |

71.5 |

38 |

286 |

- |

542 |

- |

615 |

- |

746 |

MIC-D 166 |

55 |

71.5 |

38 |

286 |

520 |

- |

727 |

- |

722 |

- |

MIC-R 106 |

95 |

54 |

28 |

371 |

- |

513 |

- |

588 |

- |

730 |

MIC-D 106 |

95 |

54 |

28 |

371 |

505 |

- |

711 |

- |

707 |

- |

MIC-R 106 |

95 |

71.5 |

38 |

371 |

- |

577 |

- |

651 |

- |

779 |

MIC-D 106 |

95 |

71.5 |

38 |

371 |

555 |

- |

760 |

- |

756 |

- |

MIC-R 251 |

140 |

71.5 |

38 |

443 |

- |

601 |

- |

681 |

- |

848 |

MIC-D 251 |

140 |

71.5 |

38 |

443 |

573 |

- |

852 |

- |

821 |

- |

MIC-R 251 |

140 |

90.5 |

57 |

443 |

- |

736 |

- |

816 |

- |

983 |

MIC-D 251 |

140 |

90.5 |

57 |

443 |

708 |

- |

988 |

- |

956 |

- |

MIC-R 411 |

300 |

71.5 |

38 |

616 |

- |

772 |

- |

- |

- |

1098 |

MIC-D 411 |

300 |

71.5 |

38 |

616 |

723 |

- |

- |

- |

1075 |

- |

MIC-R 411 |

300 |

90.5 |

57 |

616 |

- |

823 |

- |

- |

- |

1149 |

MIC-D 411 |

300 |

90.5 |

57 |

616 |

773 |

- |

- |

- |

1075 |

- |

MIC-R 411 |

300 |

90.5 |

90 |

616 |

- |

984 |

- |

- |

- |

1312 |

MIC-D 411 |

300 |

90.5 |

90 |

616 |

937 |

- |

- |

- |

1239 |

- |

MIC-R 411 |

300 |

90.5 |

102 |

616 |

- |

1030 |

- |

- |

- |

1426 |

MIC-D 411 |

300 |

90.5 |

102 |

616 |

1030 |

- |

- |

- |

1550 |

- |

|

| |

• MIC-D: Direct Acting Actuator (used on supply failure Valve–Opens)

• MIC-R: Reverse Acting Actuator (used on supply failure Valve Closes)

• All dimensions in mm.

• The Company's policy is one of continuous product improvement and the right is reserved to modify the specifications contained herein without notice.

|

|

|

|

| The Company’s policy is one of continuous product improvement and the right is reserved to modify the specifications contained herein without notice. |

|