|

UPSTREAM PRESSURE REGULATING VALVE – SERIES MIC-800 |

Manufacturer, Exporter, Wholesaler and Supplier of Automation and Instrumentation Products such as UPSTREAM PRESSURE REGULATING VALVE and our setup is situated in Pune, Maharashtra, India.

INTRODUCTION

The MSSet Series 800 upstream Pressure regulating valve is a throttling pressure control device that opens and closes to ensure the upstream pressure does not rise above a predetermined pressure. The need for constant pressure and control of the media is the most essential part of various process industries size fertilizers, petrochemicals, Refineries, Pharmaceutical Chemicals & food processing Plants.

|

|

| SPECIFICATION : |

DESIGN |

ASME B16.34 |

| BODY TYPE |

Globe. |

| VALVE FORM |

15 to 300 mm (1/2" to 12") |

| VALVE TYPE |

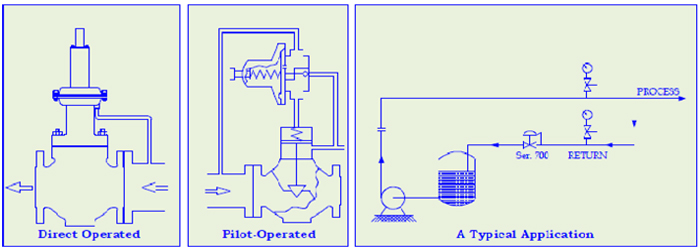

1) Direct Operated-(MIC-821) |

| 2) Angular Prv-(MIC-831) |

| 3) Pilot Operated-(MIC-851) |

| RATING |

ANSI 150 and 300, Higher on request |

| END CONNECTION |

Flanged – 15mm to 300mm (1/2" to 12") |

| Screwed – 15mm to 50mm (1/2” to 2”) |

AVAILABLE

CONFIGURATION |

As per set pressure & flow requirements,

Different diaphragm sizes are available. |

| SENSING |

Neoprene, Nitrile, Viton, EDPM, Silicon,

Teflon etc. |

DIAPHRAGM

BODY MATERIAL |

A216 Gr. WCB, CF8 / CF8M as standard.

Other on Request. |

| INTERNAL PARTS |

S.S. as standard, others on request. |

| TEMPERATURE |

25ºC to 70ºC for Nitrile elastomer parts |

| 15º to 175ºC for Viton. |

| SEAT LEAKAGE |

As per FCI-70-2 (ANSI B 16.104)

Class IV, V and VI

(STANDARD LEAKAGE RATES)

Metal to Soft Seating – Bubble tight

(Zero Leakage) |

| PRESSURE SETTING |

May be adjusted throughout a spring range

by turning the adjusting screw. |

ADJUSTMENT

PRESSURE REGISTRATION |

Internal (Standard) or Upstream Control

Line. |

|

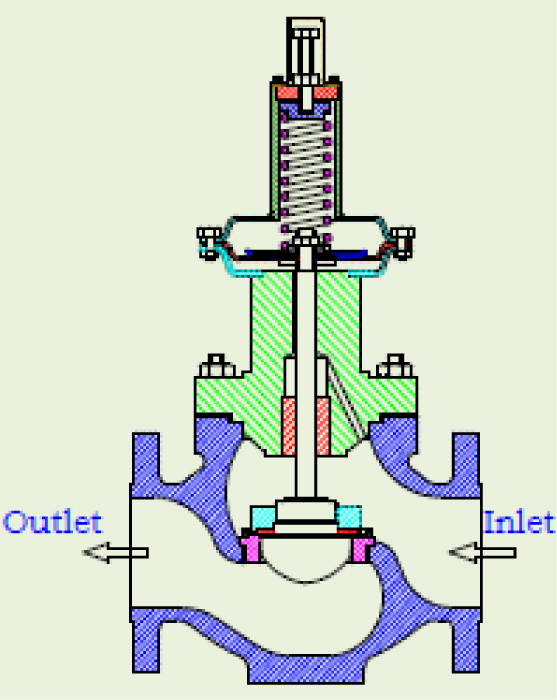

FLANGE END CONNECTION

1.1/2” AND ABOVE – MIC- 821)

|

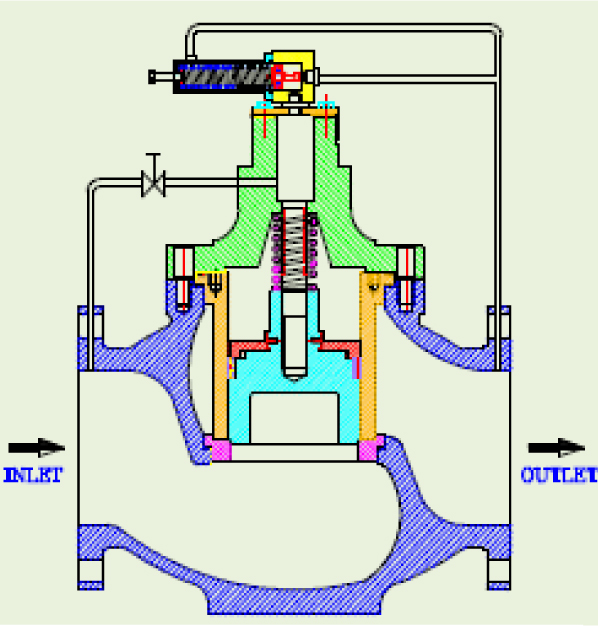

PILOT OPERATED MIC- 851 |

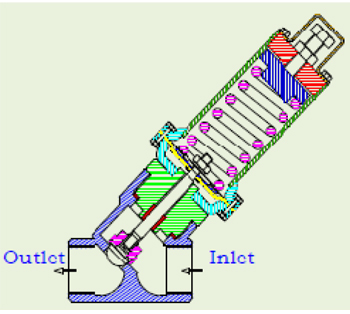

ANGULAR PRV 1/2” AND 2”

MIC- 831 |

<

|

|

|

|

DESIGN FEATURES :

- Glandless Construction: - Where positive Zero gland packing is required, the design scores

over conventional solutions such as bellow seals etc. as the gland itself is eliminated.

- Wide range of body sizes and trim sizes to satisfy varied flow requirements.

- Tight sensitively and stability of controlled pressure.

- Provides excellent tight shut off capability over long working life.

- Compact design with minimum number of moving parts.

- Simple resetting.

|

|

QUALITY AND PERFORMANCE GUARANTEE :

- Produced with Quality Systems accredited to ISO 9001: 2008 by Bureau Veritas.

- Full material certification available for all major component Parts.

- Full guarantee on design and Performance.

- All testing are performed to the requirements of ANSI B16.34.

|

| |

|

PRINCIPLE OF OPERATION

The upstream pressure is registered under the diaphragm opposing the spring when the upstream

pressure reaches the set point, the spring is compressed allowing the valve plug to open and relieve

excess pressure. |

| |

SELECTION CRITERIA :

- Familiarize yourself with the application consideration as they apply to your control

requirements.

- Inlet pressure setting and maximum allowable pressure buildup over the setting.

- Normal and maximum inlet pressure.

- Minimum, normal, and maximum flow rates.

- Name, temperature and specific gravity of controlled fluid.

- Inlet and outlet pipe size.

- Installation.

- Environmental considerations, such as noise level, corrosion, temperature extremes, etc.

- Special capabilities such as gauges, test connections, etc.

For final and optimum selection, contact MSSet sales office / factory who will assist you in

Selecting the type and size that best suits your need.

| VALVE SIZE |

mm |

1/2 |

3/4 |

1 |

1 1/2 |

2 |

3 |

4 |

6 |

8 |

10 |

12 |

| |

|

15 |

20 |

25 |

40 |

50 |

80 |

100 |

150 |

200 |

250 |

300 |

| Cv (MAX.) AT 90º OPENING |

4 |

4 |

9 |

18 |

25 |

50 |

80 |

200 |

300 |

450 |

650 |

The Company’s policy is one of continuous product improvement and the right is reserved to

modify the specifications contained herein without notice.

|

|